© 2025 Condenser Coil All rights reserved.

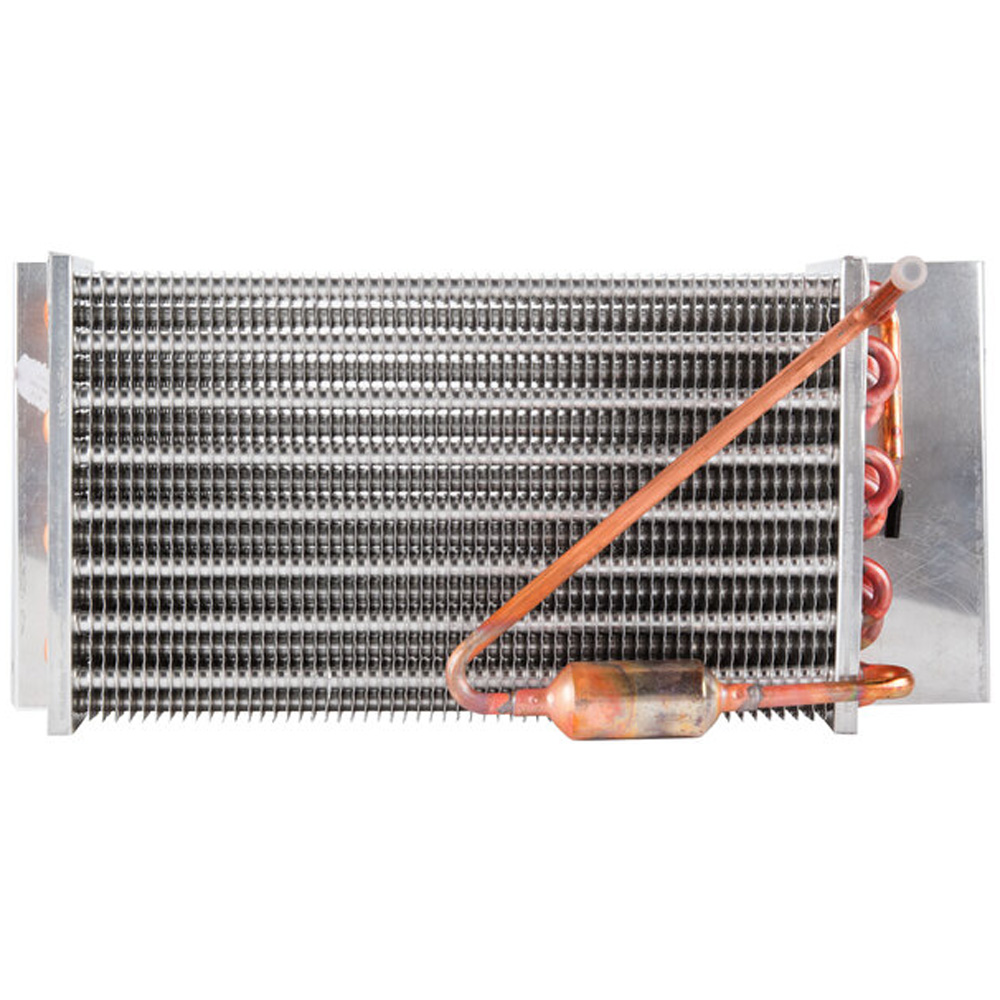

Restore your refrigeration unit to optimal efficiency with our Guaranteed Quality Aluminum Fin Copper Tube Evaporator Coil! Specifically designed as a direct replacement for select CFD-1RR and CFD-1RR-G series units, this essential component ensures your refrigeration system operates at peak performance, minimizing downtime and maximizing the lifespan of your equipment.

The evaporator coil is the heart of your refrigeration system, responsible for the vital task of absorbing heat from within the unit. Our meticulously engineered coil features a copper tube design, renowned for its exceptional thermal conductivity. Refrigerant flows through this coiled frame, efficiently absorbing heat and cooling the interior of your unit to the desired temperature.

This evaporator coil is specifically designed as a perfect replacement for the one that came standard with your select CFD-1RR and CFD-1RR-G series units. This precise compatibility ensures a seamless fit and hassle-free installation, allowing you to quickly restore your unit’s functionality.

We utilize only the highest quality materials to ensure long-lasting performance and reliability:

We stand behind the quality and durability of our evaporator coils. Our Guaranteed Quality promise ensures that you receive a product built to the highest standards, providing reliable performance and peace of mind.

A malfunctioning evaporator coil can lead to inadequate cooling, increased energy consumption, and potential damage to other components. Replacing a faulty coil promptly is crucial to maintaining the efficiency and longevity of your refrigeration unit. Our direct replacement coil allows for quick and easy installation, minimizing downtime and getting your system back up and running as soon as possible.

Don’t compromise on the performance and longevity of your refrigeration equipment. Choose our Guaranteed Quality Aluminum Fin Copper Tube Evaporator Coil for a reliable, efficient, and cost-effective solution.

Contact us today to learn more and ensure your refrigeration system continues to operate at its best!

| copper tube diameter | holds and rows pitch | fin space | holds array | fin surface | fin edge type | defrost heater |

Φ15.88mm | 50×50mm | 4-10mm | equilateral triangle | sin-wave&corrugated | flat+wave | with |

Φ15.88mm | 38Χ33mm | 2.5-4mm | equilateral triangle | sin-wave&corrugated | flat+wave | with |

Φ12.7mm | 31.75Χ27.5mm | 3-9mm | equilateral triangle | sin-wave&corrugated | flat+wave | with |

Φ9.52mm | 25Χ21.65mm | 1.5-6mm | equilateral triangle | sin-wave&corrugated | flat+wave | with |

Φ9.52mm | 31.75Χ27.5mm | 2.5-7.5mm | equilateral triangle | sin-wave&corrugated | flat+wave | with |

Φ9.52mm | 25χ21.65mm | 1.5-2.5mm | equilateral triangle | louver | flat | without |

Φ7.94mm | 25χ21.65mm | 1.5-3.5mm | equilateral triangle | flat | flat+wave | without |

Φ7.0mm | 21×12.7mm | 1.3-1.8mm | equilateral triangle | louver | flat | without |

Specification | Tube pitchA | Row pitchB | Tube size | Tube Material | Fin pitch | Fin Material |

φ7mm*21*18.2 | 21mm | 18.2mm | φ7mm | Copper Tube(SmoothTubeor Rifled Tube) | 2.0-4.5mm adjustable | Aluminumfin(Bare finorhydrophilicfin) |

φ9.52mm*25*21.65 | 25mm | 21.65mm | φ9.52mm | Copper Tube(SmoothTubeor Rifled Tube) | 2.0-3.5mm adjustable | Aluminumfin(Bare finorhydrophilicfin) |

φ9.52mm*25*21.65 | 25mm | 21.65mm | φ9.52mm | Copper Tube(SmoothTubeor Rifled Tube) | 4.0-9.0mm adjustable | Aluminumfin(Bare finorhydrophilicfin) |

φ12mm*35*35 | 35mm | 35mm | φ12mm | Copper Tube(SmoothTubeor Rifled Tube) | 4.0-10mmadjustable | Aluminumfin(Bare finorhydrophilicfin) |

φ12mm*35*30.31 | 35mm | 30.31mm | φ12mm | Copper Tube(SmoothTubeor Rifled Tube) | 4.0-10mm adjustable | Aluminumfin(Bare finorhydrophilicfin) |

φ15mm*60*30 | 60mm | 30mm | φ15mm | Copper Tube(SmoothTubeor Rifled Tube) | 4.0-10mm adjustable | Aluminumfin(Bare finorhydrophilicfin) |

Our standard packaging procedure involves the use of robust wooden crates to ensure the utmost protection of your valuable goods during transit. These crates are meticulously constructed to withstand the rigors of shipping and handling, providing a secure and reliable enclosure for your order. However, we understand that international shipping regulations vary, and we are fully prepared to adapt our packaging methods to meet the specific requirements of each destination.

For instance, when exporting to European countries, we adhere strictly to international phytosanitary regulations. In such cases, the wooden crates undergo a specialized fumigation process. This treatment effectively eliminates any potential pests or organisms residing within the wood, ensuring full compliance with European Union import standards and preventing the introduction of non-native species. This fumigation process is meticulously documented, and the crates are appropriately marked to clearly indicate their treated status.

Furthermore, we recognize that certain situations may necessitate alternative packaging solutions. In scenarios where container space optimization is of paramount concern, or if the container’s dimensions present particular constraints, we are equipped to utilize a high-grade polyethylene (PE) film for packaging. This film provides an excellent barrier against moisture, dust, and abrasion, offering a viable alternative to wooden crates when space is limited. We can employ this PE film wrapping method as the primary packaging solution, or we can customize the packaging precisely according to any unique or specialized instructions provided by our valued customers. Our ultimate goal is to ensure your order arrives at its destination in pristine condition, regardless of the challenges presented by international shipping logistics or specific customer requests.

Our high-performance condenser and evaporator coils are the silent workhorses behind a vast array of cooling and climate control systems. Engineered for efficiency and durability, these essential components are integral to numerous industries, ensuring optimal performance and reliability across diverse sectors. The image provided showcases the breadth of applications where our coils play a critical role. Let’s delve into the specific sectors that benefit from our advanced coil technology:

As illustrated in the central diagram, our coil technology features a sophisticated design incorporating:

From maintaining critical temperatures in sensitive environments to ensuring comfort in our daily lives and powering specialized industrial processes, our condenser and evaporator coils are integral to a vast spectrum of applications. We are committed to continuous innovation and providing high-quality, reliable cooling solutions that meet the evolving needs of diverse industries worldwide. This image exemplifies our dedication to pushing the boundaries of thermal management technology and serving as a trusted partner across a wide array of sectors.

© 2025 Condenser Coil All rights reserved.

Fill out the form below, our team can reply in 20 minutes.