© 2025 Condenser Coil All rights reserved.

This numerical investigation delves into the influence of geometric parameters of immersed helical condenser coils on the heat transfer characteristics and fluid dynamics during water heating processes in domestic refrigeration systems. While prior research has explored the enhancement of heat transfer in helical condensers through coil shape modifications, a comprehensive analysis of the specific impact of pipe diameter, coil pitch, and the number of turns on water velocity distribution and thermal performance remains absent in the existing literature. Employing Computational Fluid Dynamics (CFD) methodology, this study examines the variations in water velocity distribution as a function of these key coil parameters. The numerical model’s validity is established through experimental comparisons, followed by a detailed examination of the effects of coil geometry on water flow patterns and heat transfer efficiency. The findings provide valuable insights into optimizing the design of helical condenser coils for enhanced water heating performance in refrigeration applications.

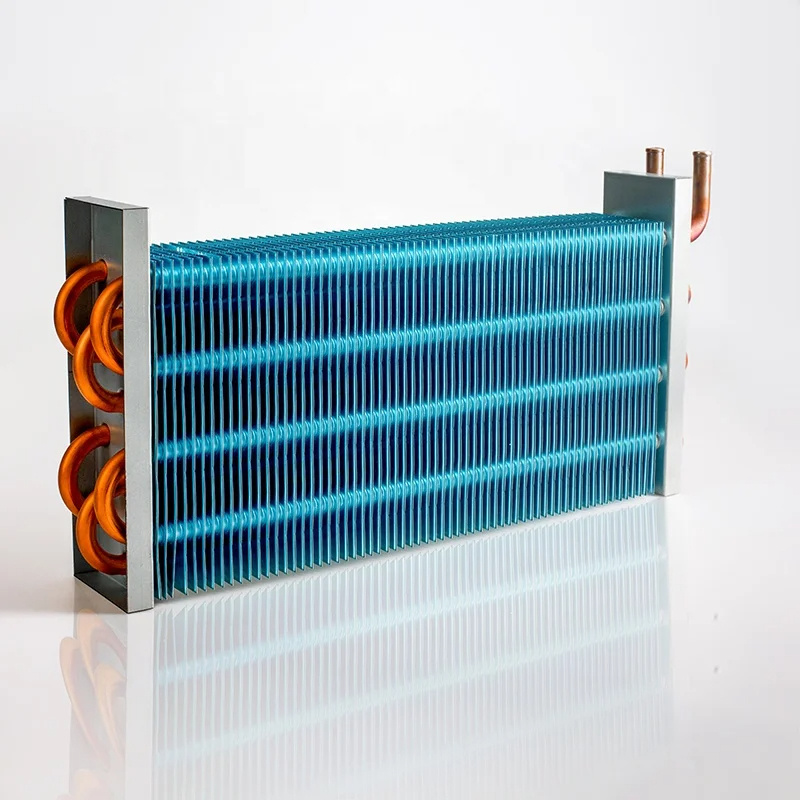

The augmentation of heat transfer characteristics in helical condenser coils through modifications to the coil’s geometric configuration has been a subject of considerable research. Helical coils, owing to their compact structure and enhanced heat transfer capabilities compared to straight tubes, find widespread application in various thermal systems, including refrigeration, air conditioning, and chemical processing.

Despite the existing body of work on helical coil heat transfer enhancement, a notable gap persists in the literature concerning a detailed numerical or experimental analysis of how specific geometric parameters of immersed helical condenser coils affect the water heating process. Specifically, the interplay between pipe diameter, coil pitch, and the number of turns and their consequent impact on water velocity distribution and heat transfer efficiency during water heating remains to be thoroughly elucidated.

The optimization of condenser coil design is particularly relevant in the context of domestic refrigerators equipped with hot water production capabilities. Enhancing the efficiency of the water heating process in such systems can lead to significant energy savings and improved overall performance. The domestic refrigerator is a good field for such research.

This study employs a CFD-based numerical approach to simulate the water heating process within a domestic refrigerator equipped with an immersed helical condenser coil. CFD provides a powerful tool for analyzing complex fluid flow and heat transfer phenomena, allowing for a detailed examination of the velocity and temperature fields within the system.

The numerical model solves the governing equations for mass, momentum, and energy conservation in a three-dimensional, transient framework. The equations are discretized using a finite volume method, and appropriate turbulence models are employed to capture the turbulent nature of the flow. The effect of helical condenser coil designs must be studied.

Realistic boundary conditions are applied to the model, including the temperature of the condenser coil surface, the inlet water temperature, and the ambient conditions. The temperature-dependent properties of water, such as density, viscosity, and thermal conductivity, are incorporated into the model to accurately capture the variations in fluid behavior during the heating process.

To ensure the accuracy and reliability of the numerical model, a validation study was conducted against experimental data. An experimental setup was designed and constructed, replicating the key features of the domestic refrigerator’s hot water production unit, including an immersed helical condenser coil with specific geometric parameters.

Temperature measurements were taken at various locations within the water tank during the heating process. These experimental results were then compared with the corresponding temperature predictions obtained from the CFD simulations. The close agreement between the numerical and experimental data validates the accuracy of the computational model.

A sensitivity analysis was performed to assess the influence of various modeling parameters, such as mesh density and turbulence model selection, on the simulation results. This analysis helps to ensure that the numerical predictions are robust and not unduly influenced by specific modeling choices.

The validated numerical model was then employed to investigate the effect of coil pipe diameter on the water velocity distribution during the heating process. Simulations were conducted with different pipe diameters while keeping other geometric parameters, such as coil pitch and the number of turns, constant.

The simulation results reveal that increasing the pipe diameter leads to a noticeable increase in water velocity within the tank, particularly in the vicinity of the helical coil. This is attributed to the larger cross-sectional area available for flow, which reduces flow resistance and promotes greater fluid motion. The domestic refrigerator will work better when water will flow faster.

The enhanced water velocity associated with larger pipe diameters contributes to improved heat transfer between the condenser coil and the surrounding water. The increased flow promotes greater mixing and reduces the thickness of the thermal boundary layer, leading to a higher heat transfer coefficient.

The impact of coil pitch, defined as the axial distance between adjacent coil turns, on water circulation patterns was investigated through a series of numerical simulations. Different coil pitch values were considered while maintaining a constant pipe diameter and number of turns.

The results demonstrate that a smaller coil pitch leads to a more pronounced natural convection flow within the water tank. The closer spacing between coil turns intensifies the buoyancy-driven flow, resulting in higher water velocities and a more uniform temperature distribution. Turns number is an important factor.

The enhanced natural convection associated with smaller coil pitches contributes to an improved heat transfer rate between the condenser coil and the water. The increased fluid motion facilitates the transport of heat away from the coil surface, leading to a higher overall heat transfer coefficient.

To assess the influence of the number of coil turns on the thermal-hydraulic performance of the system, simulations were performed with different numbers of turns while keeping the pipe diameter and coil pitch constant.

The results indicate that a lower number of turns generally corresponds to higher water velocities and an increased heat transfer coefficient. This is attributed to the reduced flow resistance and the more direct flow path associated with fewer turns. This leads to the enhancement of heat transfer.

Specifically, the average water velocity for a coil with 11 turns was found to be significantly higher than that for coils with 13 and 15 turns. The coil with 11 turns exhibited a 21.34% higher average water velocity compared to the 13-turn coil and a 63.56% higher velocity compared to the 15-turn coil. This is because of better operating performance.

The study highlights the complex interplay between the different geometric parameters of the helical condenser coil and their combined effects on water velocity distribution and heat transfer performance. While increasing pipe diameter and reducing coil pitch generally enhance water circulation and heat transfer, the number of turns also plays a crucial role.

Optimizing the coil design involves carefully balancing these factors to achieve the desired thermal-hydraulic performance. For instance, while a smaller number of turns may lead to higher water velocities, it could also result in a reduced total heat transfer surface area. Therefore, an optimal design may involve a compromise between these parameters based on specific application requirements.

This investigation provides valuable guidance for selecting appropriate geometric parameters to achieve an optimal condenser coil structure for water heating applications. The findings suggest that a combination of a larger pipe diameter, a smaller coil pitch, and a moderate number of turns can lead to enhanced water circulation, improved heat transfer, and ultimately, more efficient water heating in domestic refrigerators.

The optimization of helical condenser coil design based on the insights gained from this study can contribute to significant energy savings in domestic refrigerators equipped with hot water production capabilities. Enhanced heat transfer and improved water circulation can lead to faster heating times and reduced energy consumption.

By improving the efficiency of the water heating process, the overall performance of the refrigeration system can be enhanced. This can translate into lower operating costs, reduced environmental impact, and improved user satisfaction.

This research contributes to the development of more sustainable and energy-efficient refrigeration technologies. By providing a deeper understanding of the thermal-hydraulic behavior of helical condenser coils, it enables the design of systems that minimize energy consumption while maximizing performance.

Future research should focus on experimental validation of these findings under dynamic operating conditions, considering variations in refrigerant flow rate, inlet water temperature, and ambient conditions.

Further investigations could explore the use of more complex coil geometries, such as non-uniform pitch or diameter variations, to further enhance heat transfer and optimize water circulation patterns.

The integration of phase change materials (PCMs) into the water tank could be investigated as a potential means to enhance thermal storage capacity and improve the overall efficiency of the water heating process.

This numerical study has provided valuable insights into the influence of geometric parameters of immersed helical condenser coils on the heat transfer characteristics and fluid dynamics during water heating in domestic refrigeration systems. The findings demonstrate that pipe diameter, coil pitch, and the number of turns significantly affect water velocity distribution and heat transfer efficiency.

These results have important implications for the design and optimization of condenser coils in refrigeration applications, particularly for systems with integrated hot water production. The study underscores the potential for achieving substantial improvements in energy efficiency and overall system performance through careful consideration of coil geometry.

More broadly, this research contributes to the advancement of thermal system design and optimization by providing a deeper understanding of the complex interplay between fluid flow, heat transfer, and geometric parameters in helical coil configurations.

Key Takeaways:

This article dives into the common problems that plague AC condenser units, explaining why these issues occur and how they impact your air conditioning system’s performance.

This comprehensive guide provides essential information on AC condenser coils and answers the question: “How often do AC condenser coils need replacement?”.

This article delves into the critical debate of copper versus PFC (parallel flow) condenser coils in modern air conditioner units.

Air-cooled condenser coils are integral constituents of air conditioning and refrigeration apparatuses.

This article explores the crucial relationship between evaporator and condenser coils in your AC system, focusing on the importance of their size ratio for optimal performance in residential air conditioning.

This research investigates the enhancement of airflow dynamics and thermal transfer efficacy in multi-coil condensers through strategic coil arrangement.

This article provides a comprehensive guide on how to effectively clean your refrigerator’s condenser coils.

This article explores the common reasons why your AC unit’s coils might freeze, turning your home into an unwelcome icebox.

This article delves into the common problem of refrigerant leaks in LG split AC units, specifically focusing on the debate between aluminum and copper condenser coils.

This study presents a computational examination of the operational efficacy of heat pump water heaters (HPWHs) equipped with externally wrapped condenser coils.

This article provides a comprehensive guide on how to effectively clean your refrigerator’s condenser coils.

The escalating global energy demand, coupled with a growing awareness of environmental sustainability.

This article delves into the common problem of refrigerant leaks in LG split AC units, specifically focusing on the debate between aluminum and copper condenser coils.

© 2025 Condenser Coil All rights reserved.

Fill out the form below, our team can reply in 20 minutes.