© 2025 Condenser Coil All rights reserved.

This article delves into the critical debate of copper versus PFC (parallel flow) condenser coils in modern air conditioner units. We’ll explore the pros and cons of each type, helping you understand which coil design offers superior performance, efficiency, and durability for your HVAC system. This article is worth reading because it provides a clear comparison of two prevalent condenser coil technologies, empowering you to make informed decisions when purchasing or servicing your air conditioner, ultimately impacting your comfort and energy bills. Choosing between a traditional copper condenser and a PFC condenser is an important decision.

The condenser coil is a crucial component of your air conditioner or heat pump. It’s part of the outdoor unit and is responsible for releasing the heat absorbed by the refrigerant from your indoor space to the outside environment. Without a properly functioning condenser coil, your AC system wouldn’t be able to cool your home effectively. The condenser is a vital part of the air conditioning process.

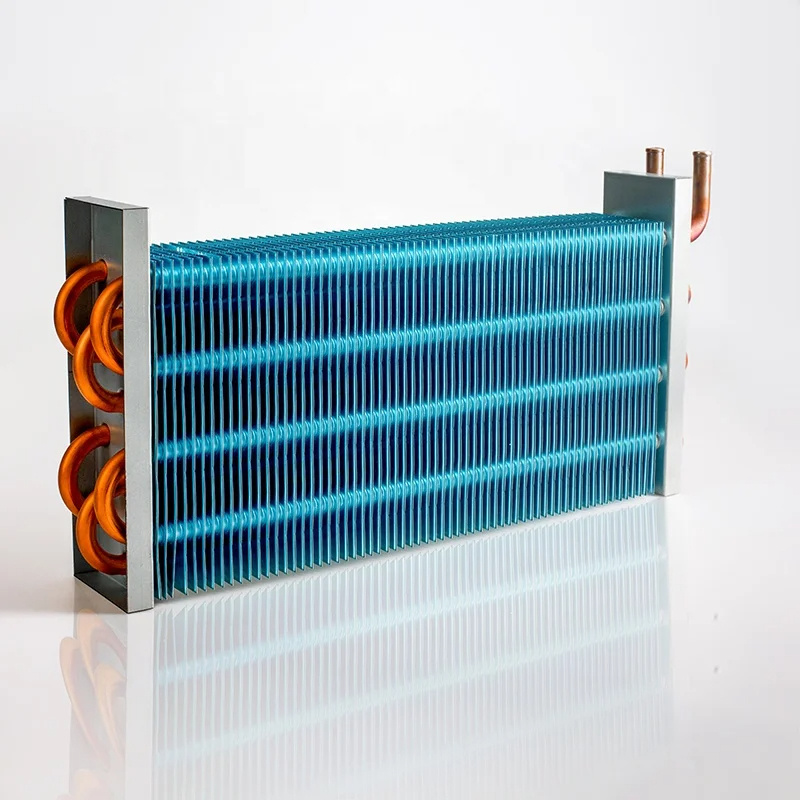

The condenser coil works in conjunction with the compressor, evaporator coil, and an expansion device. After the refrigerant absorbs heat from the indoor air in the evaporator coil, it travels to the condenser as a hot, high-pressure gas. The condenser coil, typically made of metal tubing and fins, facilitates heat transfer from the refrigerant to the outdoor air. As the heat is released, the refrigerant cools down and condenses back into a liquid, ready to repeat the cycle. The condenser coil is a very important part of your air conditioner.

Copper condenser coils have long been the standard in the HVAC industry. They are known for their excellent heat transfer properties, durability, and resistance to corrosion. Copper is a highly conductive material, meaning it can transfer heat efficiently. A copper condenser coil is very efficient.

Copper coils are typically constructed with copper tubing and aluminum fins. The fins increase the surface area of the coil, enhancing heat dissipation. Copper is also relatively easy to repair, as leaks can often be patched by welding or soldering. Copper tubing is very popular because of its heat-transferring abilities. However, copper can be susceptible to a specific type of corrosion known as formicary corrosion, which can lead to leaks over time. It is important to properly maintain copper coils.

PFC (parallel flow condenser) coils are a newer technology that has gained popularity in recent years, particularly in high efficiency air conditioners. Unlike traditional copper tube-and-fin coils, PFC condenser coils use a series of flat, parallel tubes, or micro-channels, to carry the refrigerant. These tubes are connected to multiple fins that run horizontally to increase the area available for heat transfer.

PFC condenser coils are typically made of aluminum, which is lighter and less expensive than copper. They are often marketed as being more efficient than traditional copper coils due to their larger surface area and improved airflow. However, they can be more challenging to repair, and replacement is often the only option in case of leaks or significant damage. It may be difficult to repair a damaged PFC condenser coil. It is important to keep your PFC condenser in good shape.

When comparing copper and PFC condenser coils, several factors come into play. Here’s a detailed comparison:

Choosing between copper and PFC condenser coils involves trade-offs. Copper offers durability and repairability, while PFC offers potentially higher efficiency and a lower upfront cost. PFC coils are associated with high-efficiency units.

Selecting the right condenser coil for your air conditioner depends on several factors, including your budget, climate, and specific needs. Here are some key considerations:

Ultimately, the best condenser coil for your air conditioner will depend on your individual circumstances. Consider the pros and cons of each type, and don’t hesitate to seek professional advice from an HVAC expert. If you can’t find the right coil, an HVAC professional will be able to help you.

Proper maintenance of your condenser coils is essential for ensuring the efficiency and longevity of your air conditioning system. Here are some key maintenance tips:

By following these maintenance tips, you can help ensure that your condenser coils remain in good condition, allowing your AC system to operate at peak performance.

Several signs may indicate that your condenser coil is damaged or failing:

If you notice any of these signs, it’s important to contact a qualified HVAC technician to diagnose the problem and recommend the appropriate repair or replacement.

The cost of replacing a condenser coil can vary significantly depending on several factors, including:

On average, homeowners can expect to pay between $700 and $2,500 or more to replace a condenser coil. It is important to get a quote from a qualified HVAC technician for the most accurate pricing. This is a general estimate, and the actual cost may vary. It’s best to obtain quotes from multiple reputable HVAC contractors to compare prices and ensure you’re getting a fair deal.

Finding a reliable supplier for condenser coils is crucial, whether you’re an HVAC technician or a homeowner looking to purchase a replacement coil. Here are some options:

When selecting a condenser coil supplier, consider factors such as product availability, pricing, warranty terms, shipping options, and customer reviews. It is important to choose a reputable supplier. They should be able to certify that their products are high-quality. They should also have a large product line.

Here are some answers to frequently asked questions about AC condenser coils:

Q: What is the difference between condenser coils and evaporator coils?

A: Condenser coils and evaporator coils are both essential components of an air conditioning system, but they serve different functions. The condenser coil, located in the outdoor unit, releases heat to the outside air. The evaporator coil, located in the indoor unit, absorbs heat from the indoor air.

Q: How often should I clean my condenser coils?

A: Condenser coils should be cleaned at least once a year, or more frequently if you live in a dusty area or have pets. Regular cleaning helps maintain efficiency and prevent damage.

Q: Can I clean my condenser coils myself?

A: Yes, homeowners can often clean their condenser coils using a garden hose, a soft brush, and a commercial coil cleaner. However, if you’re uncomfortable working around your AC unit or if the coils are severely dirty or damaged, it’s best to hire a professional HVAC technician.

Q: What are the signs of a failing condenser coil?

A: Signs of a failing condenser coil include reduced cooling capacity, increased energy bills, unusual noises from the outdoor unit, refrigerant leaks, and ice buildup on the coil.

Q: How long do condenser coils last?

A: With proper maintenance, condenser coils can last 10-15 years or longer. However, their lifespan can be affected by factors such as environment, usage, and refrigerant leaks.

Q: What is a PFC condenser coil?

A: A PFC condenser coil is a type of condenser coil that uses parallel flow technology, typically with flat aluminum tubes and fins, instead of the traditional copper tube-and-fin design. They are often associated with higher efficiency ratings. A PFC condenser is typically made of aluminum.

Q: How much does it cost to replace a condenser coil?

A: The cost to replace a condenser coil can range from $700 to $2,500 or more, depending on factors like the coil type, size, brand, and labor costs.

| Feature | Copper Condenser Coils | PFC Condenser Coils |

|---|---|---|

| Material | Typically made of copper tubing with aluminum fins. | Made of aluminum with a parallel flow design, using flat tubes (micro-channels) instead of round tubes. |

| Heat Transfer | Excellent heat transfer properties due to copper’s high thermal conductivity. | Offers excellent heat transfer due to the increased surface area of the flat tubes and fins. |

| Durability | Generally very durable and resistant to most forms of corrosion. | More susceptible to damage due to thinner fins and can be prone to galvanic corrosion. |

| Repairability | Relatively easy to repair leaks by soldering or welding. | Difficult to repair; replacement is often the only option. |

| Cost | Typically more expensive than PFC coils due to the higher cost of copper. | Generally less expensive than copper coils. |

| Efficiency | Offers good efficiency, especially when properly maintained. | Often associated with higher efficiency ratings (higher SEER) due to their enhanced heat transfer design. |

| Weight | Heavier than aluminum PFC coils. | Lighter than copper coils. |

| Corrosion | Susceptible to formicary corrosion in some environments. | Aluminum is prone to galvanic corrosion, especially when in contact with other metals. |

| Lifespan | Can last 10-15 years or longer with proper maintenance. | May have a shorter lifespan than copper coils due to potential corrosion and damage issues. |

| Environmental | Copper is a recyclable material. | Aluminum is also recyclable. |

| Common Uses | Widely used in residential and commercial AC systems. | Increasingly popular in high efficiency AC systems. |

| Often the preferred choice for HVAC professionals due to their reliability and ease of repair. | May require specialized cleaning techniques due to their design. |

By understanding the importance of your AC condenser coils, how often they need replacing, and how to properly maintain them, you can make informed decisions about your HVAC system’s care. This knowledge will help ensure your home stays comfortably cool while potentially saving you money on energy bills and avoiding major AC system breakdowns. Remember to consult with a qualified HVAC technician for any significant repairs or replacements to ensure the job is done correctly and safely. They will also be able to provide you with information on whether you should replace the whole unit or just the coil.

This article provides a comprehensive overview of AC evaporator coil replacement cost, as well as condenser coil replacement cost, helping homeowners understand what to expect when facing this type of repair.

This article dives into the common problems that plague AC condenser units, explaining why these issues occur and how they impact your air conditioning system’s performance.

Your air conditioning unit is a complex system with many parts working together to keep your home cool and comfortable.

The escalating global energy demand, coupled with a growing awareness of environmental sustainability.

This article delves into the critical debate of copper versus PFC (parallel flow) condenser coils in modern air conditioner units.

This article explores the critical roles of the evaporator coil vs condenser coil in your air conditioner (AC), explaining how they work together to cool your home.

This article explores the crucial relationship between evaporator and condenser coils in your AC system, focusing on the importance of their size ratio for optimal performance in residential air conditioning.

This article explains how water chillers work, focusing on the role of water in the cooling process.

This article delves into the common problem of refrigerant leaks in LG split AC units, specifically focusing on the debate between aluminum and copper condenser coils.

Air-cooled condenser coils are integral constituents of air conditioning and refrigeration apparatuses.

This article dives deep into the world of condenser coils, a crucial component of any HVAC system, exploring their function, design, and key features.

This comprehensive guide provides essential information on AC condenser coils and answers the question: “How often do AC condenser coils need replacement?”.

This article explores the critical roles of the evaporator coil vs condenser coil in your air conditioner (AC), explaining how they work together to cool your home.

© 2025 Condenser Coil All rights reserved.

Fill out the form below, our team can reply in 20 minutes.